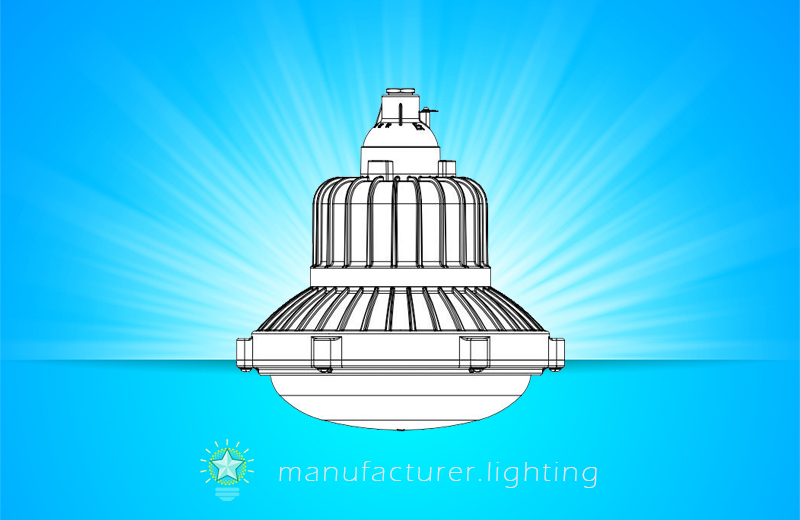

Explosion-proof lights are completely enclosed and capable of withstanding an explosion of a specific gas or vapor which may occur within the luminaires, and furthermore shielding against the ignition of a specific gas or vapor encircling the enclosures by sparks, flashes, or explosion of the gas or vapor within. Explosion-proof lighting fixtures are employed in Class I Division 1 Groups C and D, Class 1 Zone 0 Groups C and D, Class II Division 1 Groups E, F, and G, and Class III areas, for instance, areas having a very high gaseous atmosphere including oil and gas refineries, and they are further effectively utilized on board off-shore drilling rigs, on-shore drilling rigs, on oil-and-gas transport tankers, mines and, in a nutshell, in every place whereby, to one degree or another, flammable and explosive fumes are constantly present. LED explosion-proof lights provide a powerful and energy efficient replacement for traditional hazardous location luminaries. The aluminum body is powder coated for extra durability as well as an appealing visual appearance, give this light exceptional durability and resistance to vibration and impacts. Explosion proof LED lights typically feature a thermal management system that makes use of internal cooling fins to draw heat away from the LEDs. This makes it possible for longer lamp life and more consistent light output. The lamp housing is weatherproof and constructed of copper-free aluminum alloy featuring a powder coat finish, and is gasket sealed, with stainless steel hardware for corrosion resistance. The anti-glare lens minimizes glare in applications where the operator may have direct visual contact with the light source. High efficiency LED drivers are engineered to provide reliable operation in even the harshest environments.