A motion sensor is a device that detects physical movement or senses occupancy within an environment. It is designed to capture the kinetics or presence of objects of interest, and convert the detected changes into control signals that can be used to automate the operation of other connected devices. With rising expectations for security, safety and efficiency, motion controlled lighting is gaining momentum. Adaptive controls based on motion detection and occupancy sensing are widely installed to control individual fixtures or networked systems for interior illumination of residential spaces, commercial buildings, and industrial facilities, as well as exterior illumination of building perimeters, parking areas, walkways, pathways and driveways.

Occupancy Detection

Motion sensors are often used to monitor the controlled area for occupancy and signal this information to a lighting controller, which then decides whether to turn on the light, or to dim up the light and by how much. The goal of lighting design is to provide the right amount of light where and when it is needed, with appropriate lighting quality, for the lowest power density. Lighting must comply with ever-changing energy codes while creating optimum visual conditions to ensure occupant satisfaction. Energy efficiency is especially a priority in commercial buildings, industrial, and outdoor lighting applications due to the long operating hours and relatively high wattages typically involved. Lighting constitutes about 15% - 20% of the total energy consumption in commercial buildings and industrial facilities. Roadway, street and area lighting is a drain on resources. Energy management through occupancy-based controls can capture significant savings by switching off or dimming down lights during low traffic hours. Occupancy sensors are useful not only to address flexible operating hours, but also to provide zonal controls in areas with irregular usage patterns.

Motion sensors can be programmed to be vacancy sensors, which are designed to automatically turn off when no presence of occupants is detected. Unlike occupancy sensors which automatically turn on lights upon detection of human presence, vacancy sensors are programmed to not turn on lights and require the lights to be switched on manually when sensing the presence of an occupant. The manual-ON feature of vacancy sensors prevents false-ON events and thus could potentially yield greater energy savings than occupancy sensors. Many energy programs, such as California Energy Commission's Title 24, offer control credits for absence detection.

Intrusion Detection

Security lighting is installed to create a perception of security and facilitate the use or effectiveness of other security devices such as video surveillance cameras and interactive alarms systems. Lighting systems often work in unison with intrusion detection systems to create effective zones of protection and aid in the detection and deterring of intruders. Motion sensors are commonly employed to control security lighting and activate other security devices of an intrusion detection system. Adding motion triggers to security lights transforms lighting into an active security element that can create a more psychologically deterring effect while facilitating the use or effectiveness of other security devices. With motion detection features, intrusion detection systems can be automated to trigger video recording, sound an alarm, and/or send an alert.

Types of Motion Sensors

Motion sensors can be divided into passive and active types. A passive sensor doesn't actively send out signals but detects some type of energy emitted by the object of interest or sense the change of some natural field of energy that occurs when a target enters its field. An active sensor transmits its own energy and detects a change in the reflected energy created by the presence or motion of the object of interest. Active sensors are generally less affected by environmental conditions and have fewer nuisance alarms (false tripping) than passive sensors because they are transmitting signals designed to be compatible with those conditions. Passive sensors generally consume very little power as they do not transmit energy. Low power requirement makes passive sensors ideal for battery-operated motion detectors. Passive sensors generally require an unobstructed line of sight (LOS) between the sensor and any target to be detected, whereas some types of active occupancy sensors transmit energy capable of penetrating physical barriers such as walls, plastic and glass. LOS sensors are usually visible sensors that are in plain view of an intruder. Non-LOS sensors can be designed as covert sensors which can be designed aesthetically behind a housing made of materials that do not obstruct signals.

The three most common types of motion sensors used for occupancy and intrusion detection are passive infrared (PIR), microwave and ultrasonic sensors but other types such as dual-technology sensors are also used. They are classified as volumetric sensors that detect motion in a volume of space.

Passive infrared (PIR) sensors

A PIR sensor detects changes in the amount of infrared radiation created by the movement of a heat source such as the human body. PIR sensors respond to electromagnetic radiation in the wavelength band between 7 and 14 nm. The pyroelectric material used in a PIR sensor detects the heat emitted from a heat source relative to the ambient temperature and generates an electric charge. When the changes in the detection zone exceed an established threshold, the control circuitry will trigger a signal that enables a light or activates an alarm.

Pyroelectric detectors are generally available in dual or quad element versions. A slight mechanical stress by any external force or any change in background temperatures can cause the hypersensitive pyroelectric element to generate a charge indistinguishable from that caused by the infrared radiation. This may affect the operation and the accuracy of the single element type sensors. The dual and quad element types of PIR sensors have the inherent immunity from inaccuracies suffered by the single element type. The elements are connected to the electronic circuit in a way to produce a positive differential only when a variable thermal radiation due to motion of a heat source takes place. The positive differential is the difference between the two signals obtained from each pyroelectric element. The voltage generate by each pyroelectric element when exposed to spurious heat or an external force is equal, and this signal will be canceled at the input of the circuit.

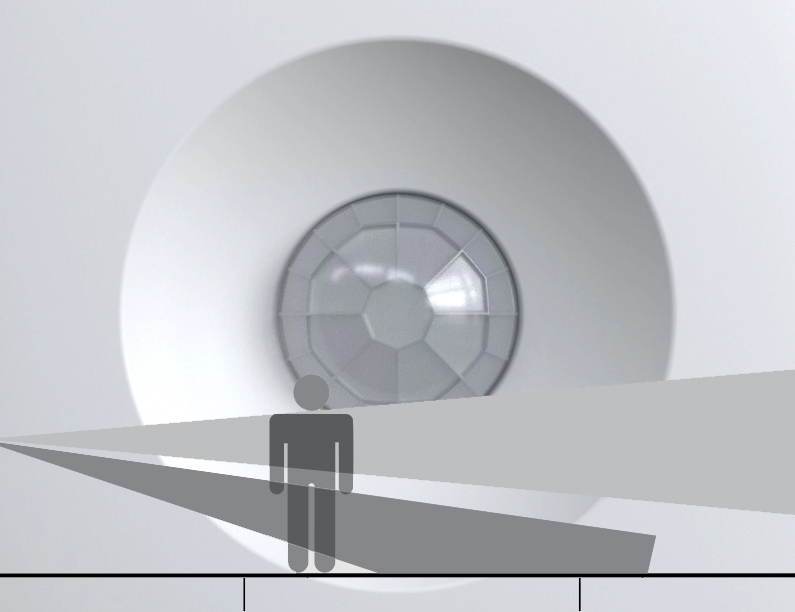

The pyroelectric modules are usually incorporated in a housing with a plastic window that allows in infrared radiation. The window itself may be molded plastic Fresnel lens that directs energy toward the sensor while serving as a filter to limit the wavelengths to 7-14 nm and protecting the sensor from environmental contaminants. The segments of the Fresnel lens create distinct radial zones of detection that expand the field of view of the small sensor elements. The design of the lens determines the overall detection angle and viewing area. Care should be taken that may the faceted lens may create big gaps (dead zones) between segments when the sensor is designed for a very wide field of view.

PIR sensors are the most commonly used volumetric sensors for detecting major motions such as occupants or intruders moving in and out of a space. They are small, inexpensive, low power, and are available in multiple options for an easily customizable detection pattern. The maximum detection distance of PIR sensors ranges from 4 m to 12 m depending on the size of target. Changes in the infrared signature of a heat source are most visible when the motion is lateral to the sensor. PIR sensors only detects movement and are not as effective for low motion activities. Sensitivity decreases proportionally to distance between the sensor and object.

PIR sensors are strictly for line of sight use and cannot see through obstacles such as partition walls. High ambient temperatures can present a challenge for PIR motion sensors because the operation of a PIR sensor requires the object of interest to have a temperature profile identifiably different from its background. Therefore, the sensor should be placed away from other heat sources such as space heaters, HVAC vents, and sunlight.

Microwave sensors

Microwave sensors detect occupancy and movement based on the Doppler frequency shift between the transmitted and received signal. The active volumetric sensor transmits electromagnetic waves with frequencies that are more often found in radar systems and reflects off an object that is in the sensor's field of view. The Doppler frequency is the difference between the frequency of signal originating at the Radar and the frequency of the reflected waveform. Microwave systems are available in two basic configurations: monostatic and bistatic. A monostatic microwave sensor employs a single antenna (transceiver) to transmit and receive signals. A bistatic microwave sensor consists of a transmitter antenna and a receiver antenna with each located at either end of a perimeter sector to form a line-of-sight system.

Microwave sensors designed to control lighting systems or security cameras are usually of the monostatic type that typically operates in the X band RF region (7 to 11 gigahertz). Monostatic microwave sensors are volumetric sensors and have a large detection pattern that ranges from 9 meters up to 50 meters depending on the radar signature of the object. Microwave sensors may be stacked to increase the height of detection zone, thereby enhancing the detection capabilities. Since microwave sensors operate in the high-frequency spectrum, they works well in most environmental conditions. Their accuracy is not affected by moving air, changes in temperature or humidity. High frequency waves pass through standard walls, glass, plastics, sheetrock and wood, which opens up new ways to implement these sensors.

In general, microwave sensors offer much greater coverage, sensitivity and immunity than PIR sensors. They are ideal for large spaces, wide-open areas, and applications that require the detectors to be immune to environmental disturbances. However, careful consideration on location is needed in certain applications as the highly penetrative signals can cause nuisance alarms to be triggered by motion adjacent to, but outside, the detection zone. Nuisance alarms can also be caused by interference between adjacent microwave sensors when they operate in the same frequency. Fortunately, there're products that allow users to select from several different frequencies. Another disadvantage of microwave detectors is that they cannot distinguish between a live person and other moving objects.

Ultrasonic sensors

Ultrasonic sensors use the Doppler principle to detect motion. They broadcast sound waves at frequencies above the human and animal audibility ranges. Any moving object within its detection zone will alter the frequency of the sound waves. Ultrasonic sensors are good at detecting minor motion such as arm movements up to 9 meters away. They can detect movements that are not within the line of sight, such as movements around partitions. Ultrasonic sensors fill the space with signal and leave no coverage gaps within their detection zones. They have a greater coverage area than PIR sensors and are best suited to confined spaces like offices, conference rooms, bathrooms, breakrooms, storage rooms, areas with cabinets and shelving, and areas requiring 360-degree coverage.

A major disadvantage of these sensors that they are prone to false signals if they are placed in close proximity to areas with heavy airflow and sources of air vibration. In addition, ultrasonic frequencies used in sensors may interfere with hearing aids and other ultrasonic sensors. Because ultrasonic sensors continuously emit sound waves and listen for a change in frequency of the reflected sound, they require more power. As such, ultrasonic sensors are only available as a hard-wired systems.

Dual-technology sensors

Dual-technology sensors combine two different types of sensors in one assembly to lower the false or nuisance alarm rates. A dual-technology sensor is most often intended to achieve absolute alarm confirmation by electronically connecting two sensors using an "AND" gate logic function. A valid trigger will be generated only when both technologies sense an event within a predetermined interval. Dual-technology sensors can also be configured using "OR" gate logic to enable either sensor technology to generate an alarm independent of the other. This configuration ensures the highest probability of detection. However, the likelihood of nuisance alarms will be greatly increased. Two commonly used combinations of dual-technology sensors for motion detection occupancy sensing are PIR-ultrasonic and PIR-microwave. Utilizing both passive infrared and active ultrasonic technologies, PIR-ultrasonic sensors are best suited to interior spaces with irregular occupancy patterns and facilities where maximum reliability is important. The PIR-microwave dual-technology go well with both interior and exterior applications.