Upgrade your lighting infrastructure for advanced energy management with TPPL® – Tubular Professional Performance Lighting, a connected, sensor-rich LED lighting solution specially designed to address tough application challenges in industrial facilities and hazardous areas. Industrial lighting used to be a drain on your resources because it places high demands not only on the performance of light fixtures but also on their reliability. Traditional HID fixtures draw excessive amount of power and require high frequency maintenance, this adds up to a soaring total cost of operation and renders a facility at a competitive disadvantage. With its nature of high luminous efficacy and solid state light emission, LED lighting provides compelling benefits over legacy technologies and has inspired an extensive range of applications in the industrial sector.

Industrial Lighting Needs Networked Intelligence

Just because LED lighting is inarguably more efficient, it doesn’t mean everything will fall into place in a world where competition is white-hot. Every profitable business relies heavily on cost optimization and constantly hunts for a high ROI lighting solution. Merely retrofitting with LED fixtures does not unlock the full potential of LED technology. The function of a space and the complexity of a task vary tremendously from production to warehousing, and from industry to industry. Therefore every lighting solution needs to be tailored to maintain the comfort, safety and productivity of people working in the space while reducing operating costs to a minimum. The complex, expansive installation of industrial light fixtures deems effective light management a serious contributor that helps facilities owners to create a productive work environment, all while meeting the stringent, ever-changing energy codes.

IoT-enabled On-demand Lighting Solution

Superior controllability of LEDs provides features and benefits that are not obtainable with traditional light sources. The real revolution comes when intelligence and communications capabilities are added to LED lighting systems which are subsequently transformed into digitally controllable nodes. These networked lighting nodes can be programmed to provide on-demand lighting through a central network control system. Seamlessly integrating intelligent LED lighting into a Bluetooth mesh, TPPL delivers significant energy savings through aggressive lighting controls provided by a contextually-aware Internet of Things (IoT) infrastructure. TPPL was developed to be the value carrier of the Lighting-as-a-Service (LaaS) energy solution which is a collaborative offering between PSPL, a technology and business development company based in the Netherlands, and DIETAL, a French lighting manufacturer. By incorporating energy efficient lighting, distributed intelligence and networking into a robust system, TPPL transforms lighting from a financial burden to a strategic asset for high-performing facilities.

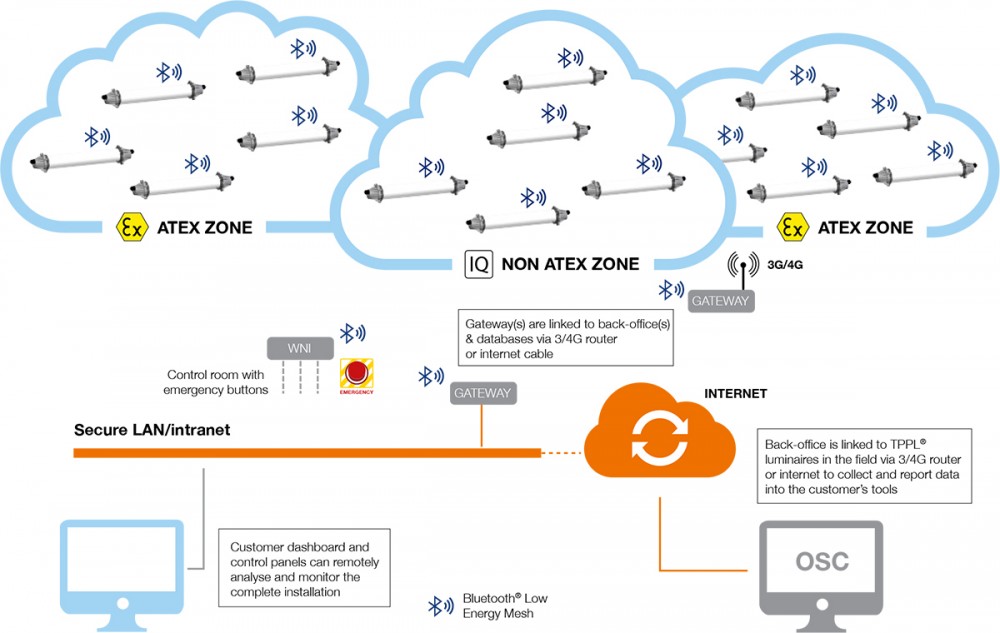

The TPPL connected lighting solution consists of three functional blocks: the Atex and IECex certified smart LED fixtures, Bluetooth mesh network, and central IoT system. The convergence of solid-state lighting with the IoT unlocks actionable, facility-wide intelligence that facilitates lighting automation. Manufacturing facilities and hazardous industrial locations have always demanded dependable lighting that thrives in even the harshest environmental conditions. The distinction of TPPL LED fixtures is the marriage of best-in-class components and rigorous engineering. This brings longevity to the lighting nodes and makes high efficacy lighting a lifetime feature. Intelligent lighting controls with programmable occupancy sensing, daylight harvesting and task tuning provide highly responsive and adaptive lighting. Bridging the real world with the digital world, the cyber-physical lighting system aggregates and analyzes sensor-generated insights to help you maximize operational and energy efficiency. TPPL IoT lighting offers scalable intelligence capabilities and works across all project sizes.

Performance Engineered TPPL Fixtures

The TPPL light fixture is a waterproof, weather resistant tubular LED luminaires that measure 100 mm in diameter. The tubular LED luminaires come available in 800 mm, 1200 mm, and 1700 mm length options which are designed to accommodate 18.5W, 37.5W, and 56W LED strip modules respectively. Inside the luminaire the linear LED modules take advantage of high performance Nichia LEDs which deliver high lumen density and high quality light in SMD packages with high temperature stability. In conjunction with high efficiency optics and power supplies, the luminaire delivers an impressive system luminous efficacy of up to 155 lm/W and clean, consistent < 4 SDCM, 70 CRI white light in a 5000K color temperature that keep workers alert and motivated. Thanks to a factory-interchangeable optical reflectors made of high specular aluminum, the linear light fixture provides a choice of three beam patterns, including 60°beam angle (HB) for high bay lighting applications with a mounting height over 6 meters, standard 120° beam angle (STD) for mounting height from 3 to 6 meters, and 180°batwing beam pattern (BW) for wide ambient illumination in spaces with mounting heights below 3 meters.

All the benefits of LED lighting can only be unleashed when the temperature of the LED junction point is tightly controlled. Exceptional thermal engineering ensures no deterioration in conversion efficiency from electrical to optical power as well as no color shift toward the higher end of the spectrum. Thermally optimized LED packages are solder mounted to a metal core printed circuit board (MCPCB) which efficiently transfers the LED heat flux to an aluminum heat sink. Low thermal resistance design makes the entire assembly extremely efficient in heat dissipation. This not only prevents excessive phosphor thermal degradation, but additionally protects the high temperature sensitive electrical components from being thermally stressed.

The natural lumen depreciation over the life of the luminaire is compensated by a programmable LED driver which provides constant light output (CLO) power supply. This feature will gradually increase the circuit wattage of the LED module to ensure minimum 90% system lumen maintenance over 15 years. The single-end powered LED luminaire features universal voltage compatibility (120-277VAC or 176-276VDC). The adjustable output current (AOC) driver is 3-100% dimmable and has a full DALI IEC 62386-102 and DALI IEC 62386-207 compliant control interface. An RS-485 local interface with high resistance to lighting current surges and fast transients provides high surge immunity on system level. Built-in smart thermal protection automatically tunes down LED current (-50% between +50 and +60°C) and switches off the light when the external ambient temperature rises above °C to prevent overheating. Along with short circuit, overvoltage and overcurrent protection, full set of advanced protection features contribute to a super-low failure rates (less than 3% @ 87,000 hours).

Thrive in Harsh Environments

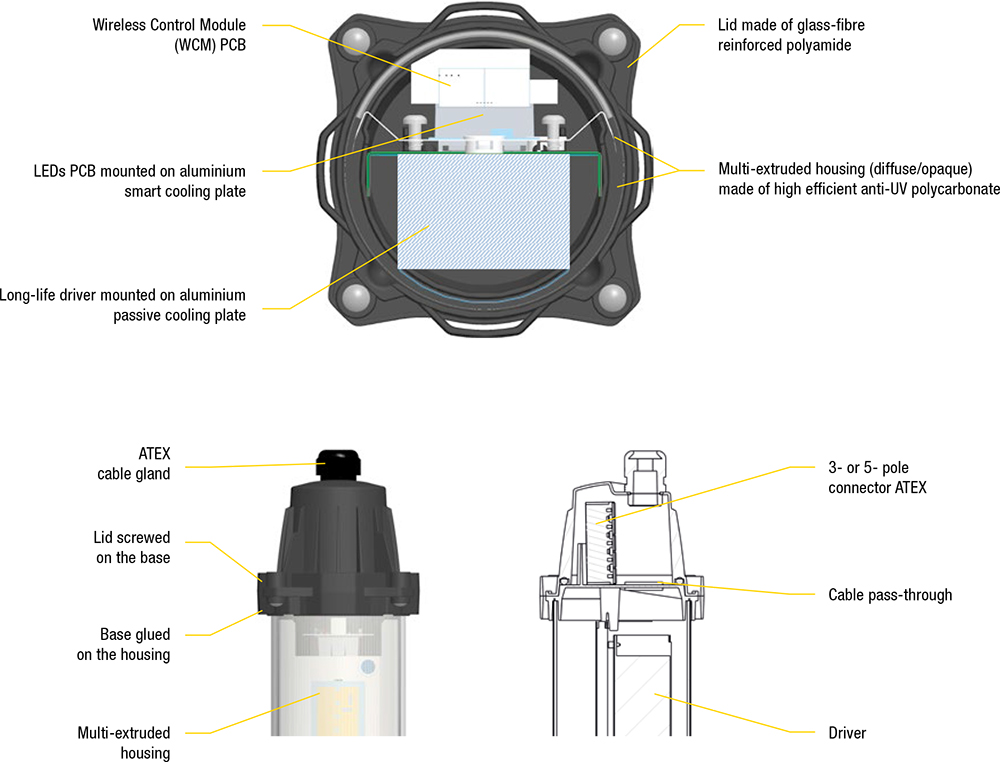

TPPL LED luminaires are engineered to perform in environments beyond your worst expectations. Rugged construction, corrosion-resistant housing and high watertight integrity give this exterior rated luminaire the ability to survive corrosive atmospheres, extreme temperatures, and heavy vibration. An impact resistant, thermally conductive, and UV stabilized housing made of co-extruded polycarbonate and techfiller provides durable protection and offers a combination of high light transmission and uniform light diffusion. The high strength tubular housing is sealed with a glass-fiber reinforced polyamide lid and polycarbonate endcap for IP66 level ingress protection. Waterproof electrical connection is made through the entry with an ATEX cable gland. TPPL light tubes support feed-through wiring for daisy chain connection of multiple fixtures. TPPL LED tubes can resist high mechanical impact with 20-joule shock energy. The tubular form factor and smooth surface of the fixture enable natural cleaning and removal of dirt and debris.

ATEX Certified for Hazardous Areas

The industrial light fixture is Atex and IECex certified for both gas and dust environments. In many industries, the explosive characteristics of the air mixtures of gases, vapors, or dusts pose a significant threat. Oil and gas facilities, chemical processors, pharmaceutical facilities, sewage treatment plants, off-shore and dockside installations, and other hazardous locations place critical demands on luminaries. The ATEX luminaires is designed and built to deliver high quality, energy efficient illumination with superior protection and full compliance with the international requirements for lighting in hazardous sites. They can be used in locations made hazardous due to the presence of a mixture with air of flammable substances in the form of gas, vapor or mist (Zone 1, 2; II 2G Ex e ib mb op is IIC T5 Gb) and an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur (Zone 21, 22; II 2D Ex tb ib mb IIIC T75°C Db). Beside the ATEX certified fixtures (EX), an Industrial Quality version (IQ) is available to offer the same performance, reliability, quality and wireless functionalities. Only specific Atex and IECex certification elements are omitted. EX and IQ can be mixed in the same network to be controlled and monitored in the same way.

Scalable, Secure Bluetooth Architecture

The network robustness for TPPL IoT-enabled lighting system is provided by the Bluetooth mesh network which provide direct, peer-to-peer communication between nodes. With an embedded a Bluetooth radio and a wireless control module (WCM) that is seen by the system as a node with its own unique ID, each fixture is able to establish multiple routes to the central network (3G gateways/LAN). Unlike most of wireless protocols are loaded with overhead, Bluetooth has been optimized to provide nearly instantaneous response to input from switches, sensors, or mobile devices. Tens of thousands of nodes can share a single secure network via secure gateways or WNIs (wireless network interfaces). Each wireless network group includes at least two Bluetooth gateways. The node is added automatically to the network and can be commissioned immediately. Maximum distance between 2 lighting nodes is 70 meters in open field conditions. The installation is designed in a way that every node has at least 2 or more neighbors for robust connectivity.

Abound in Intelligence

The smart TPPL luminaires offer a suite of intelligence features, which enable them to adapt to the environment and respond to user interaction. There are three different layers of control for the TPPL fixtures. The built-in ambient light sensor provides dusk-to-dawn lighting control. The CLO driving circuit enables the LED fixture to deliver constant lumen output through the life of the product. The intelligent overtemperature protection provides protective dimming and deactivation. Third party systems provides a second layer of control, and include occupancy sensors, people tracking sensors, manual override devices, and alarms which can be seamless integrated with the fixture to provide more control over the environment. The third layer of control is cloud-based. The IoT lighting nodes can be customized to provide a series of complicated, time-sensitive dimming and on/off switching instructions such as autonomous operation using smart scheduling algorithms and demand driven lighting.

Web-based Management

TPPL provides a full-featured central management system for integrated monitoring and management of the lighting network. The off-site service center (OSC) allows for real-time monitoring, online firmware upgrade, and statistical reporting. The OSC also allows operators to manually switch the control mode for specific light group. Web based customer dashboard and control panel enable a unified real-time view of all data assets and allow users to extract knowledge and actionable insights. TPPL luminaires are commissioned to be placed in groups and on a map with a GPS location. The integrity of the entire network (Fixture, Bluetooth and LAN/3G) is routinely checked by the system using a loop test to address each fixture. Re-commissioning can be executed centrally via the OSC Luminizer® dashboard and control software.